South Ibr Corrugated Roofing Double Layer Roll Forming Machine

Basic Info

Model No.: ibr roof

Product Description

Model NO.: ibr roof Thickness of Raw Material: 0.3-0.8mm Power of Cutting: 4kw Material of Roller: S45c with Heat Treatment Color of Machine: Blue or as Your Request Material or Shaft: S45c Specification: ce HS Code: 84552210 Suitable Material to Produce: Galvanized Steel Main Power of Machine: 7.5kw Material of Cutter: Cr12MOV HRC52-58 Dricing of Machine: by Chain Diameter of Shaft: 75mm Trademark: ZD OR OEM Origin: China IBR DOUBLE LAYER ROLL FORMIGN AMCHINE

1.Main parameters of IBR CORRGAUTED DOUBLE LAYER MACHINE :

Parameters of raw material

Note:

If the plate with a coating,the coating should be consistent with coating inspection standards of the relevant color-coated,should not have skin off,so as not to effect quality of Roll Forming.

standards of the galvanized steel,should not have zinc layer off,so as not to effect the quality of roll forming.

2.Main technical conditions of the forming line:

Temperature:-10ºC~35ºC :-10ºC~35ºC

Voltage:380V,50HZ,3P(or according to customer request)

Air pressure:0.6~1.2Mpa

Total Power:≈4+3kw(normal speed),

Color:

Production capacity:0-12 m/min(normal speed,with cutting),

Dimension (L*W*H): L≈ 6.8m, W≈ 1.2m, H≈ 1.5 m

Specification of the shipping container:(the number is pre-estimated ≈, final data should be confirmed in two weeks before delivery.)

3.Main components:

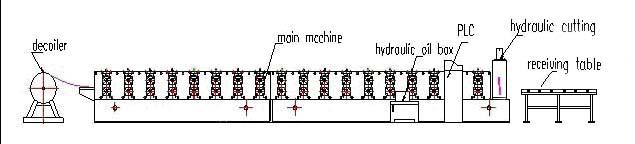

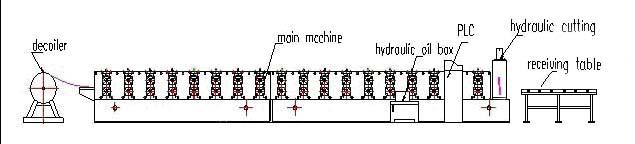

4.Flow Chart of Roll Forming Machine:

Decoiling → Roll Forming →Hydraulic cutting→Collecting table

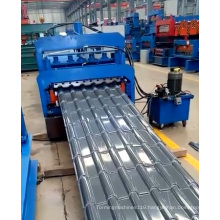

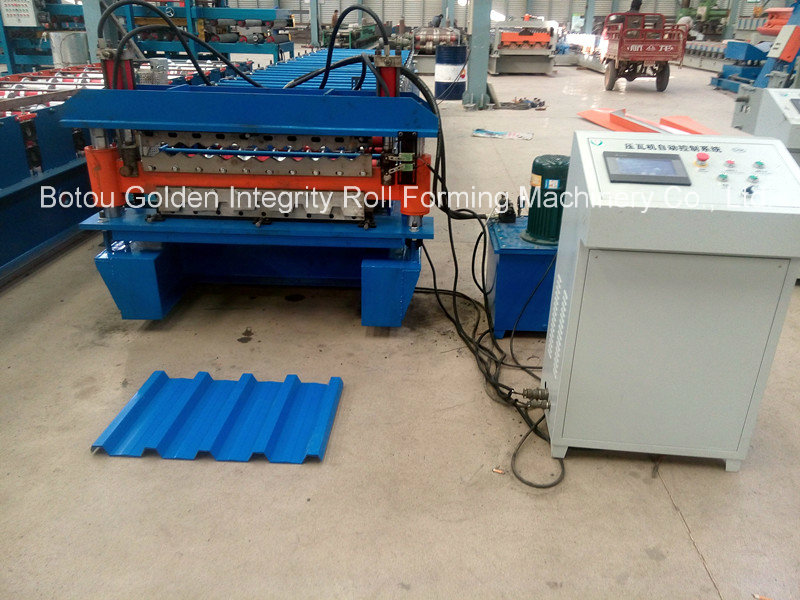

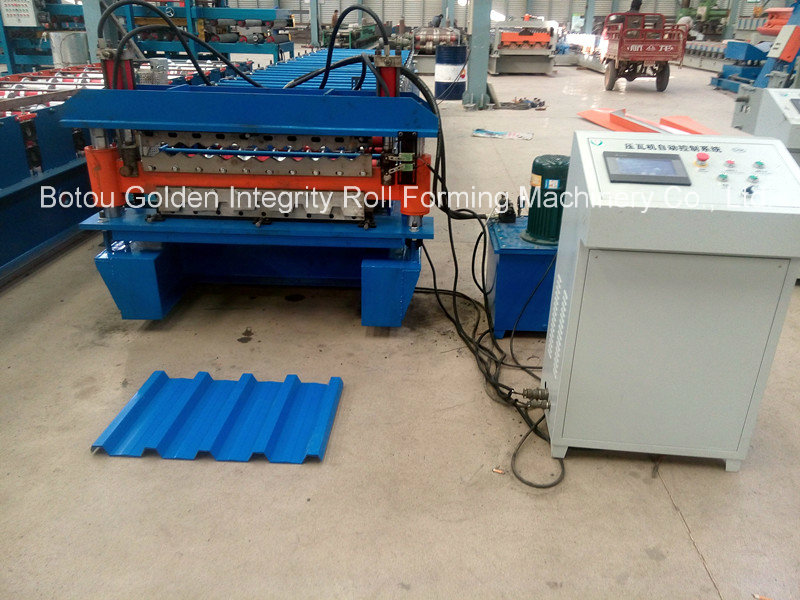

5.Photos of Machine:

6.Technology parameters:

The weight of machine is about3.1tons

The total dimension of machine:6800(L)*1200(W)*1500mm(H)

6.1Manual decoiler:

lCapacity of uncoiler:5tons

lExpansion of segment:Manual

lRotation of segment:Manual

lNumber of segment:4

lRange of segment expansion:480-520mm

lOperation method:Manual

lQty: 1

6.2 Guiding system:

To keep the material straight

lEntrance and adjustable wheel: 2rolls

lQty: 1

6.3Main forming machine:

lCoil thickness:0.25-0.7mm

lmotor type: 3 phase asynchronous motor

lMain motor power:4kw+3kw(normal speed),

l lApprox. 13groups roller including

l lRoller : S45C with quenching treatment,Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

lShaft: Diameter of max shaft: ø70mm(hardening and tempering)

l l Transmission type:by one inch chain

l Qty: 1

6.4Hydraulic cutting:

l lMaterial of blade: Cr12Mov,HRC58-62

l lLength measuring: Automatic encoder length measuring

lType of cutting:Cutting after forming:Cut the sheet after roll forming to required length.No need to change mold for different sizes

lCutting motion:The main machine automatically stops and the cutting will take place.After the cutting,the main machine will automatically start.

lPower of motor:3kw

6.5Product support frame

l lSize: L 3m x W0.5m

l lQty: 2

6.6PLC Control System

The whole line is controlled by PLC and touch screen. The PLC system is with high-speed communication module, it is easy for operation. The technical data and system parameter can be set by touch screen.

l lControl the cutting length automatically

l lAutomatic Length measurement and quantity counting

(precision 3m+/-2mm)

l l Voltage:380V, 3 Phase 60Hz (As per buyer`s request)

We can also provide you with the following brands: (Optional, price need to be confirmed)

Spare parts(free)

Contact us if you need more details on Ibr Double layer roll forming machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machine、Roof Tile Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Main parameters of IBR CORRGAUTED DOUBLE LAYER MACHINE :

Parameters of raw material

| Material | Thickness | I.D | Yield Strength |

| Q235 gi&ppgi& galvalume | 0.25-0.7mm | 508mm | <=235mpa |

Note:

If the plate with a coating,the coating should be consistent with coating inspection standards of the relevant color-coated,should not have skin off,so as not to effect quality of Roll Forming.

standards of the galvanized steel,should not have zinc layer off,so as not to effect the quality of roll forming.

2.Main technical conditions of the forming line:

Temperature:-10ºC~35ºC :-10ºC~35ºC

Voltage:380V,50HZ,3P(or according to customer request)

Air pressure:0.6~1.2Mpa

Total Power:≈4+3kw(normal speed),

Color:

| Main body | Cylinder |

| RAL 5015 (SKY BLUE) | RAL3020 (TRAFFICE RED) |

Production capacity:0-12 m/min(normal speed,with cutting),

Dimension (L*W*H): L≈ 6.8m, W≈ 1.2m, H≈ 1.5 m

Specification of the shipping container:(the number is pre-estimated ≈, final data should be confirmed in two weeks before delivery.)

| Container | 20FT | 40FT | 40HQ |

| Number | 1 |

| No. | Name | Unit | Qty |

| 1 | 5 tons manual un-coiler | SET SET | 1 |

| 2 | Feeder | SET | 1 |

| 3 | PLC control system | SET | 1 |

| 4 | Main Forming Machine | SET | 1 |

| 5 | Hydraulic cutting | SET | 1 |

| 6 | Collecting table | PCS | 2 |

| 7 | Spare parts | SET | 1 |

4.Flow Chart of Roll Forming Machine:

Decoiling → Roll Forming →Hydraulic cutting→Collecting table

5.Photos of Machine:

6.Technology parameters:

The weight of machine is about3.1tons

The total dimension of machine:6800(L)*1200(W)*1500mm(H)

6.1Manual decoiler:

lCapacity of uncoiler:5tons

lExpansion of segment:Manual

lRotation of segment:Manual

lNumber of segment:4

lRange of segment expansion:480-520mm

lOperation method:Manual

lQty: 1

6.2 Guiding system:

To keep the material straight

lEntrance and adjustable wheel: 2rolls

lQty: 1

6.3Main forming machine:

lCoil thickness:0.25-0.7mm

lmotor type: 3 phase asynchronous motor

lMain motor power:4kw+3kw(normal speed),

l lApprox. 13groups roller including

l lRoller : S45C with quenching treatment,Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

lShaft: Diameter of max shaft: ø70mm(hardening and tempering)

l l Transmission type:by one inch chain

l Qty: 1

6.4Hydraulic cutting:

l lMaterial of blade: Cr12Mov,HRC58-62

l lLength measuring: Automatic encoder length measuring

lType of cutting:Cutting after forming:Cut the sheet after roll forming to required length.No need to change mold for different sizes

lCutting motion:The main machine automatically stops and the cutting will take place.After the cutting,the main machine will automatically start.

lPower of motor:3kw

6.5Product support frame

l lSize: L 3m x W0.5m

l lQty: 2

6.6PLC Control System

The whole line is controlled by PLC and touch screen. The PLC system is with high-speed communication module, it is easy for operation. The technical data and system parameter can be set by touch screen.

l lControl the cutting length automatically

l lAutomatic Length measurement and quantity counting

(precision 3m+/-2mm)

l l Voltage:380V, 3 Phase 60Hz (As per buyer`s request)

| No. | Name | Brand | Country |

| 1. | PLC | DELTA | Taiwan,China |

| 2. | Tocuh Screen | DELTA | Taiwan,China |

| 3. | Frequencyer | DELTA | Taiwan,China |

We can also provide you with the following brands: (Optional, price need to be confirmed)

Spare parts(free)

| No. | Name | Quantity | Country |

| 1 | Encoder | 1pcs | China |

| 2 | Rely | Several | China |

| 3 | Fuses | 2pcs | China |

| 4 | Control Button | 2pcs | China |

| 5 | Sensor | 4pcs | China |

Product Categories : Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Roof Panel Forming Machine (880)Stone Coated Roof Forming MachineQJ EPS 980 Sandwich Panel Making MachineQJ Steel sheet Hole Punching Machine /metal sheet hole punching machineQJ Hydraulic Ridge Cap Roll Forming MachineQJ-475 Steel Roofing Standing Seam Making Machinewholesale color steel arch roll forming machine made in chinahydraulic light steel keel making machinehigh speed automatic door frame making machine from chinaQJ 40-256-768 Glazed Tile Roll Forming Machine MachineryCustomed Color Steel Tile Roll Forming Machine Made In ChinaCladding metal Steel Floor Decking Cold Roll Forming MachineBest Roof Sheet Roll Forming Machine PricesCangzhou Forward Color Steel Frame Profile Making MachinePopular Botou Double Layer Sheet Roll Forming MachineCorrugated Steel Roof Sheet Roll Forming Machine Production Line