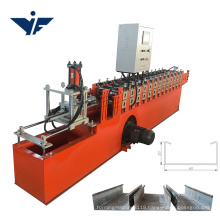

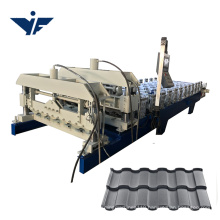

Steel Roll Forming Machinery

Basic Info

Model No.: 30--195-995

Product Description

Model NO.: 30--195-995 Condition: New Usage: Roof Suitable Material: PPGI/Gi Forming Stations: 16 Speed: 10m-15m/Min Motor: 4+4kw Specification: Jcx HS Code: 845221000 Certification: SGS, CE, ISO Customized: Customized Transmission Method: Machinery Thickness: 0.3mm-0.8mm Wall Thickness: 16mm Chains: 25.4mm Trademark: jcx Origin: Hebei China Steel Roll Forming Machine

1.1 Feeding width: 1200mm

1.2 Effective width:995mm

1.3 Material thickness: 0.3-0.8mm

Product Description

Standard Equipment of Machine:

The Technical Parameters:

2. Process flow: Decoiling--feeding---forming---cutting---production

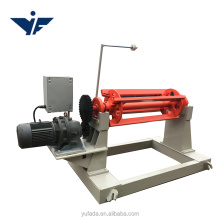

3. Manual Decoiler:

3.1 Material coil inner diameter: 450mm-700mm

3.2 Max coil width: 1200mm

3.3 Carrying capacity: 5T

4. Forming Device:

4.1 Number of forming steps: 14 steps

4.2 Shaft material: 45# steel with harden treatment, outer diameter 75mm

4.3 Roller material: 45# steel

4.4 Main motor power: 5.5kw

4.5 Forming speed: 8-10m/min

4.6 Voltage: 380V/50Hz/3 Phase

5. Cutting Device:

5.1 hydraulic cutter

5.2 blade, puncher and mold material: Cr12 steel with quenched treated 60-62C

5.3 cutting system: Advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.

6. Controlling Device:

6.1 screen: 5.7 inch Taida screen from Taiwan

6.2 PLC: Taida DVP14ES from Taiwan

6.3 coder: Japanese Omron E6C2

7. Hydraulic:

7.1 Advanced hydraulic system from Taiwan

7.2 Power: 4kw

8. Simple output frame: Simple frame weld bu #8 U bar, 1 PCS of 3m Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Forming Machine、Cutting. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.1 Feeding width: 1200mm

1.2 Effective width:995mm

1.3 Material thickness: 0.3-0.8mm

Product Description

Standard Equipment of Machine:

| Uncoiler | 1 set |

| Guiding Equipment | 1 set |

| Roll Forming Equipment | 1 set |

| Post Cut Equipment | 1 set |

| Hydraulic Station | 1 pc |

| PLC Control | 1 pc |

| Supporter Table | 2 pc |

The Technical Parameters:

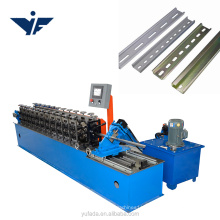

| Suitable raw material | Color steel sheet; Galvanized steel sheet |

| Thickness of the material | 0.8m to 1.2mm |

| Yield strength of material | 235Mpa |

| Uncoiler' s loading capacity | Max. Capacity: 5000Kgs. (can be increased to be 10 tons) |

| Forming speed | About 15-20m/min |

| Main motor power | 18Kw(Depend on final design) |

| Hydraulic station power | 5.2Kw(Depend on final design) |

| Controling System | Mitsubishi PLC & converter |

| Votage | 380V, 3 phase 60Hz or according to at buyer' s requirment |

| Quantity of the roller group | At lest 15 groups(depend on final design) |

| Machine dimension | About 18m*1.5m*1.4m(depend on final design) |

| Total weight | About 10000kgs(depend on final design) |

2. Process flow: Decoiling--feeding---forming---cutting---production

3. Manual Decoiler:

3.1 Material coil inner diameter: 450mm-700mm

3.2 Max coil width: 1200mm

3.3 Carrying capacity: 5T

4. Forming Device:

4.1 Number of forming steps: 14 steps

4.2 Shaft material: 45# steel with harden treatment, outer diameter 75mm

4.3 Roller material: 45# steel

4.4 Main motor power: 5.5kw

4.5 Forming speed: 8-10m/min

4.6 Voltage: 380V/50Hz/3 Phase

5. Cutting Device:

5.1 hydraulic cutter

5.2 blade, puncher and mold material: Cr12 steel with quenched treated 60-62C

5.3 cutting system: Advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.

6. Controlling Device:

6.1 screen: 5.7 inch Taida screen from Taiwan

6.2 PLC: Taida DVP14ES from Taiwan

6.3 coder: Japanese Omron E6C2

7. Hydraulic:

7.1 Advanced hydraulic system from Taiwan

7.2 Power: 4kw

8. Simple output frame: Simple frame weld bu #8 U bar, 1 PCS of 3m Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Forming Machine、Cutting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Roof Panel Forming Machine (880)Stone Coated Roof Forming MachineQJ EPS 980 Sandwich Panel Making MachineQJ Steel sheet Hole Punching Machine /metal sheet hole punching machineQJ Hydraulic Ridge Cap Roll Forming MachineQJ-475 Steel Roofing Standing Seam Making Machinewholesale color steel arch roll forming machine made in chinahydraulic light steel keel making machinehigh speed automatic door frame making machine from chinaQJ 40-256-768 Glazed Tile Roll Forming Machine MachineryCustomed Color Steel Tile Roll Forming Machine Made In ChinaCladding metal Steel Floor Decking Cold Roll Forming MachineBest Roof Sheet Roll Forming Machine PricesCangzhou Forward Color Steel Frame Profile Making MachinePopular Botou Double Layer Sheet Roll Forming MachineCorrugated Steel Roof Sheet Roll Forming Machine Production Line