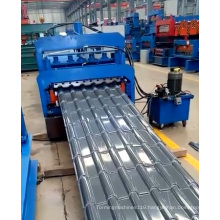

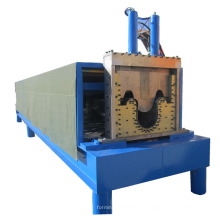

Furring channel rollformer furring channel rollforming line

Basic Info

Model No.: ZT-Furring channel - rollformer

Product Description

Furring channel rollformer furring channel rollforming line

Furring channel rollformer furring channel rollforming line is a full automatic CNC rollformer can manufacturer the furring channel, the batten channel, the Omega channel and the C stud and U track channel. batten channel, the Omega channel and the C stud and U track produced by the rollformer , material is Galvanized steel, it used to make the ceiling structural. Furring channel rollformer furring channel rollforming line is custom-made according to the sizes and thickness of the ceiling channels.

Below is the specifications of the Furring channel rollformer furring channel rollforming line

Speed 70m/min[without punching holes]30m/min[with punching holes]

Thickness 0.3mm-0.8mm

Controlling Siemens PLC

Manual De-coiler 1 ton Electric de-coiler

Feeding machine Pneumatic

Punching press Brand Famous Brand Yangli Press

Roller station 10 stations[yx27,32x27,32mm]10 stations[yx10x21mm]12 stations[yx22x63mm]

Servo motor tracking cutting 1 set

Roller material Gcr15 finish machining after quenching HRC58-62℃,chromium coating.

Shaft material and diameter 45# steel finish machining,diameter is ¢56mm

Main power 5.5 kw

Hydraulic press 12 Mpa

Hydraulic power 3.0kw

Blade material Cr12Mov, quenching HRC 58-62℃

Hydraulic pressure 12Mpa

Length tolearance 3m±1.5mm

Voltage 380V, 50HZ,3Ph

Transmission 1,0 inch single chain

structural Pillar structure

Color Company color

Size Length*Width*Height 5.5m*1,3m*1.0m

Product Categories : Steel Frame Machine > C Stud Rollformer